Precision, efficiency, versatility, automation, repeatability, and enhanced productivity are the key benefits of CNC machine tools

High Precision and Greater Accuracy

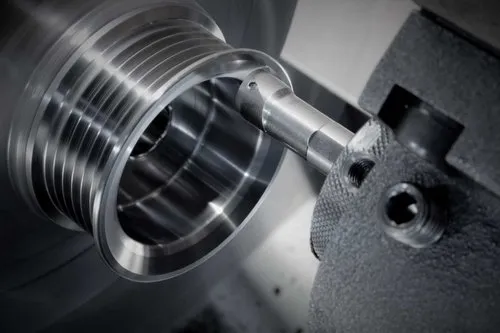

CNC machine tools are characterized by unparalleled precision and accuracy that is essential for a number of industries in which one has to deal with delicate designs and narrow tolerances. The idea is that CNC machines work with the precision that can be defined as almost microscopic, with a barely noticeable error margin. First and foremost, precision is crucial in such industries as aerospace and medical equipment manufacturing because any substantial standard deviation can lead to catastrophic consequences. The secret behind the CNC machine tool is its control systems that guide cutting tools: the precision is being controlled through signals that equal 0,001-0,0001 “, which allows getting almost exact dimensions. Therefore, such versatile control ensures a reliable ability to produce parts with complex geometry and quick adaptability because the machining surface becomes easy to satisfy the high demands of precision typically defined by the aerospace and medical industries. The outcome is especially likely to meet the applicable quality standards.

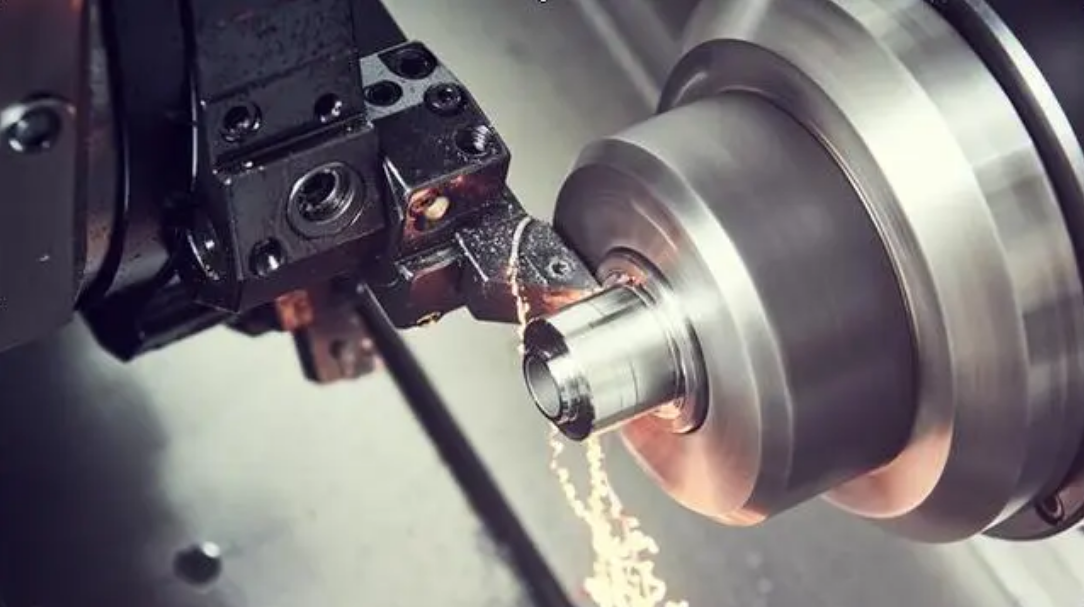

Increased productivity and efficiency

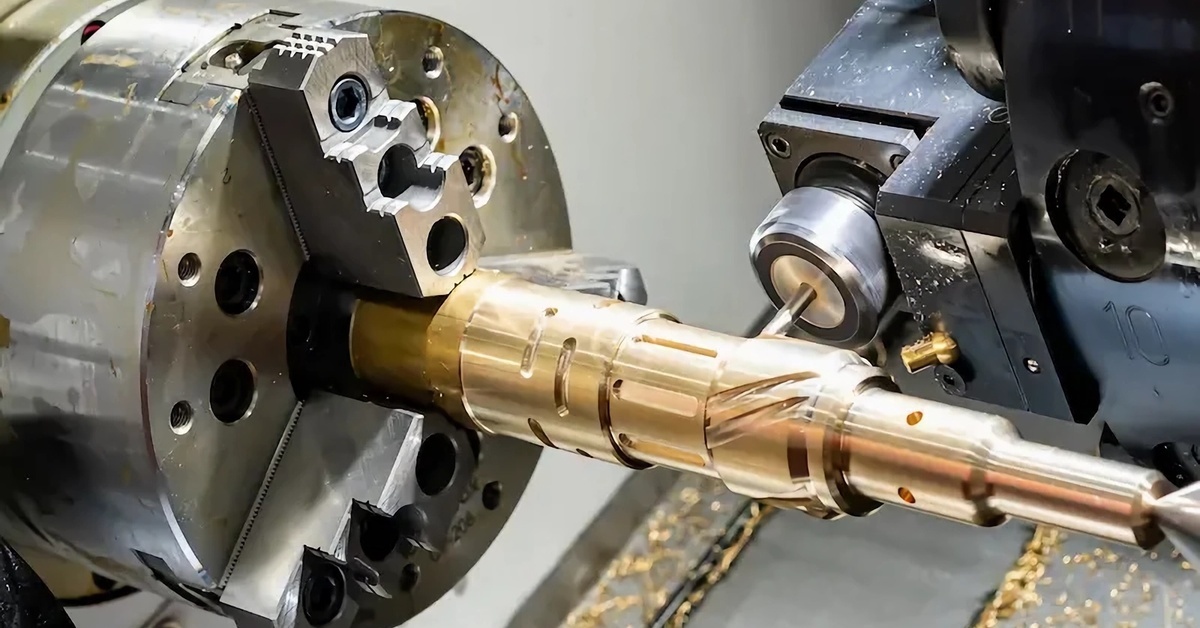

In addition to the precision, CNC machine tools have unprecedented efficiency in production processes. Whereas manual machines require operation by humans that implies fatigue, inaccuracy due to the human factor, and relatively low pace, CNC machines are able to execute tasks for unlimited time without losing efficiency. At the same time, the works of CNC machines are also fast: for example, CNC lathe is able to provide precision parts at a masterful turnover rate of 200-1000 revolutions a minute. In other words, with the help of CNC machine tools, it is possible to proceed with the intricate work with a speed which is multiple times in excess to that of the manual machining.

Shorter workflows and reduced response time

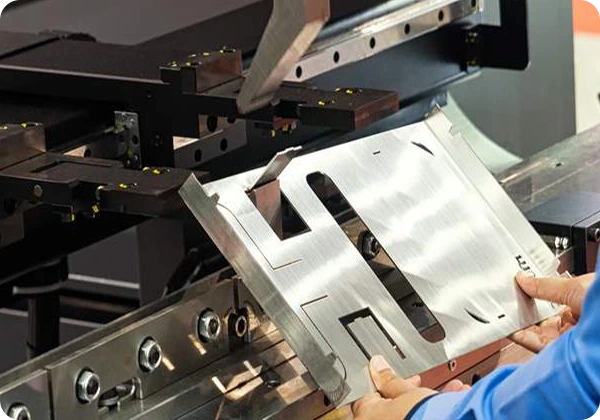

CNC machine tools also facilitate workflow for a number of tasks that do not require the setup and constant changes of the setup between different stages of works. The idea is that CNC machine tools work in an almost “plug and play” mode once they are programmed: the setup time and changes of tools are reduced significantly because different kinds of tools can be kept inside the machine, which makes them quick to change without having to change the machine. Moreover, due to the ready-to-go setup, more than one tool can also work on one task at the same time, significantly reducing the lead time: that is very important for companies that struggle with a demand that far exceeds the room for fulfillment. In sum, to keep the competitive edge by satisfying customer demand through timely deliveries and extremely short turnarounds, more and more companies choose CNC machine tools and handle intricacies to secure high efficiency and provide customers with such a level of service.

CNC machine tools provide numerous benefits, with one of the most significant being the increased and broadened applicability across different types of work and industries. Such machines can be employed with various materials, ranging from metals such as aluminum, steel, or various composites and plastics to those of differing characteristics, making them indispensable in any manufacturing setting. Moreover, these may be used to support various machining types, including milling, turning, drilling, or grinding, enabling manufacturers to create almost any type of part, product, or component they may require. Whether making intricate and complex aerospace components or small and precise medical implants, CNC machine tools can offer the versatility needed to complete nearly any type of manufacturing work.

Reduced material waste

These types of tools, especially in combination with new CAD/CAM software and machining tools, can reduce the waste of materials that are integral to their production. This benefit comes from the precision of the manufacturing process as it allows for the creation of the most efficient designs with materials removed only when absolutely required. Additionally, the particularities of CNC machining allow for nearly no material or kerf width loss, as the machines are equipped with precision cutting methods and tools. This can have a lower cost of production due to reduced waste and higher productivity in terms of production value with greater material yields.

Higher safety and reduced labor costs

CNC machine tools are considered safer to use in all manufacturing settings than those that rely on human labor for the operation, as the risk of injury to workers and operators is substantially lowered. The high degree of automation and necessary safety features and interlocks make the likelihood of accidents and injuries both low and easily avoidable. Additionally, the process is largely automated and repeated, meaning that less skilled labor is required for the process, saving companies operating such equipment on labor costs.

High throughput and scalability

It is undeniable that CNC machine tools are highly efficient and scalable due to their throughput and scalability characteristics. The throughput of CNC machines is a key factor in their high efficiency. According to Symcox and Smith, CNC machine tools are designed to process large numbers of workpieces rapidly. The throughput of these machines is significantly increased as a result, which is excellent in rapidly delivering the client’s orders. Additionally, CNC machines can operate continuously due to high-speed automation technologies. These characteristics have made CNC machines the best tool in rapidly carrying out simple tasks within a span of a few hours. Some of the machines can process hundreds of components in just an hour, increasing their productivity and generating unprecedented levels of output.

Tight scheduling in production

These machines are highly efficient and allow for rapid response to customers’ orders due to the rapid setting of new job tasks. CNC can run the production plan without any setup because it operates in a very dynamic environment. Reports show that due to the continuous process, a new task can be executed every ten minutes. In the traditional process, it was hard to achieve high throughput and productivity within a day because it required daily setup. It has not only reduced lead times but also has facilitated better organization of production schedules.

Scalable automation solution

Automation is a major factor that has facilitated high throughput and scalability because it allows for flexibility in the overall process. It is possible to scale the CNC machines’ throughput by setting the production lines to operate of commissioning machines based on demand. Automation of the production lines through the use of robots in moving materials and other subsystems has played a very essential role in increasing productivity and efficiency. It means that inter-process interfacing automation has to be prepared if the output has to be enhanced in the long-run.

Continuous production process

Rapid adjustment of the production line and critical component machining and assembly is another strength that has always been emphasized. It implies that CNC machine tools ensure that there is always a continuous flow of production without being interrupted. Case in point is the utilization of advanced scheduling algorithms, and tracking of jobs and machines on the tool path. Some of the basic complementary activities include defending the production process from congestion and restricted buffer storage.

Subtractive manufacturing technique

There is no doubt that CNC machine tools have to ability to produce a wide range of components because they can work on any material. Symcox and Smith have clearly shown that CNC is excellent in thinking across the limit, especially in tackling complex geometry and workpiece size. It means that CNC can produce simple components used in the consumer goods sector up to the highly complicated aero-engine components. It is an approach that has always been utilized in the creation of new products and components. Additionally, a good example of machining facilities is the ability to incorporate various metals, ceramics, polymers, and composite-based workpiece materials. It also includes provisions where a single machine can be operated depending on the ever-changing schedules. The machining characteristics of CNC are such that they can be employed in a wide variety of applications and product flexibility settings.

enhanced abilities

CNC machine tools provide manufacturers with an opportunity to do things they had always wanted to do. The majority of people who operate a CNC machine tool for the first time experience the invigorating sensation that comes from the fact that they can do something new and impressive, not to mention the fact that they can do it right now. These machines use the most reliable modern technologies that help operators reach the unprecedented level of precision, repeatability, and efficiency. CNC technology provides a lot of benefits for the manufacturers as it increases the level of productivity by fueling the efficiency and speed and helps operators produce high-quality results by improving the level of precision and control.

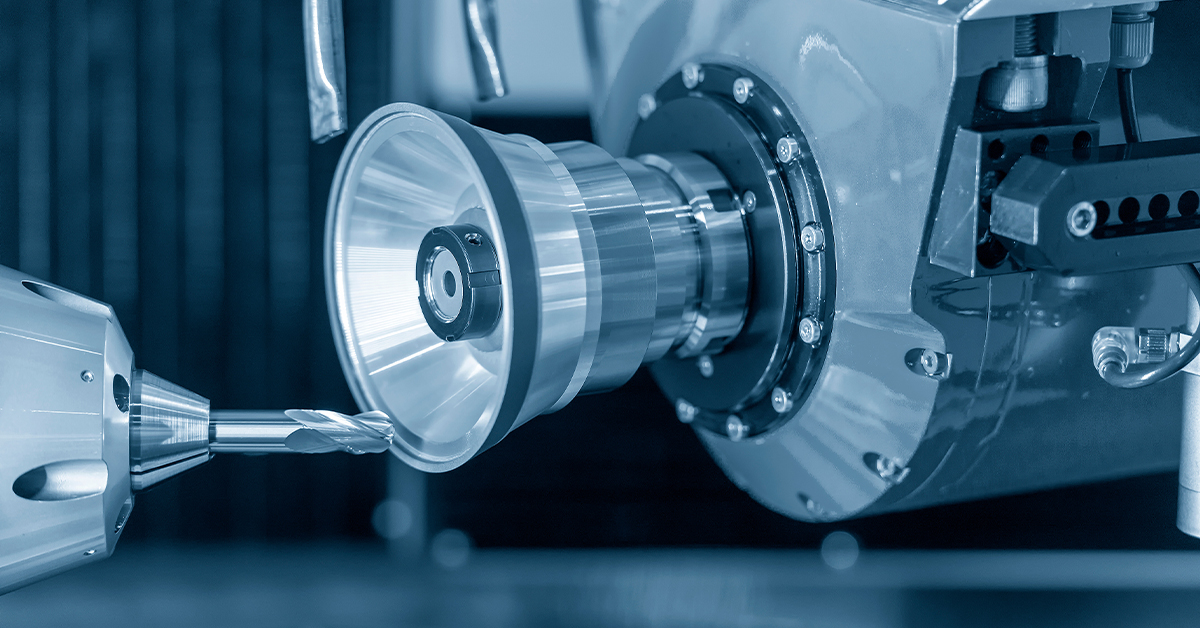

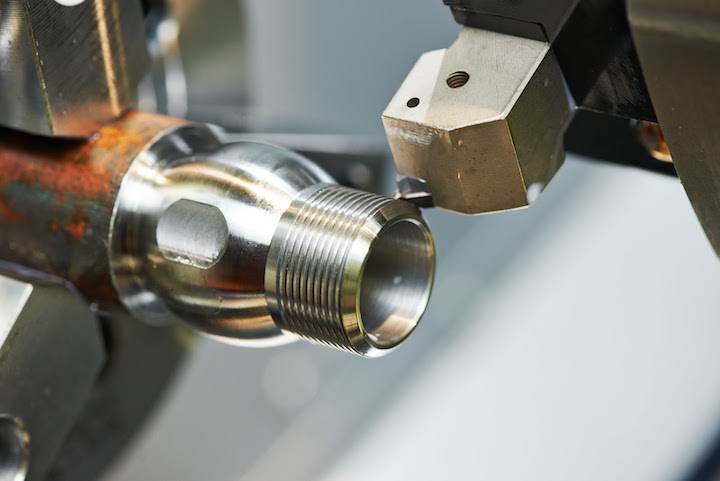

Workpiece geometries and machinability

CNC machine tools provide their users with the opportunity to produce more complex and intricate parts in a faster and more efficient manner. They create opportunities for achieving more precise and reliable results by leveraging highly controlled cutting operations and precisely constructed tools. CNC machine tools can be programmed to produce machine parts through a wide range of machining operations, such as milling, turning, drilling, or grinding, with a high level of accuracy and repeatability. In general, CNC machine tools produce workpieces with complex geometries and little surface geometry that would be difficult or impossible to produce using manual approaches. Multi-axis machining tools rotate cutting tools on the X,Y, and Z axes, which allows producing highly-detailed final products.

Material waste and optimal geometries

CNC machine tools are especially beneficial in terms of material waste as they enable operators to cut down on waste and significantly reduce material expenses. A broad choice of materials and advanced cutting tools and software allows manufacturers to select the most optimal material and customize it in the most proficient way.

Customization and personalization. CNC machine tools allow manufacturers to offer their customers the services of customization and personalization. That is, they enable manufacturers to adjust the production of a unique product that suits an individual customer. Using special programs, the manufacturer can program the machine to produce a specific component whose uniqueness can be perfectly tailored to individual requirements. The personalization of the product can vary from order to order and can be as simple as engraving a custom logo on a metal component. Moreover, the product can be quite fragile, intricate, and wooden with complex patterns, which can be a decoration. The personalization of products increases customers’ confidence in the purchases they make, as they receive a product that meets their needs 100%. They can recommend similar services to their needs, and purchase them more.

Continuous process improvement. CNC machine tools also help manufacturers continuously improve the production process. It helps operators through specific performance indicators that provide them with real-time data on how their machine tools are working. Monitoring the machine allows manufacturers to be able to analyze the current state of the process and decide what needs to be constantly adjusted and improved for a more accurate and smoother workflow. Decision-making support helps to prevent such bottlenecks and machine operators have the right to make decisions. This not only improves the effectiveness of the production process but also helps to constantly monitor its progress and look for ways to lead. Improvement processes help operators perform tasks and maintain their equipment in the most effective state.

Empowered workforce. By using this technology, the workforce also benefits. Operating a CNC machine requires a lot of knowledge and skills that users lack after the training in the field of the manufacturing industry. As a result, people learn how to program the machine from scratch and how to set it up, adjust the process, optimize it, and work with it. This expands the manufacturing capabilities and increases interest in working in the manufacturing industry, allowing operators to start their careers in a new technology field. CNC machines also allow them to advance their careers by constantly learning and modifying their qualifications to evolve. They feel more skills and experience through the use of advanced technologies that facilitate the operator’s work in the industry. This, in turn, leads to investing in their training and education, and this will be useful for the manufacturer in the long term.

Capable of producing the most complex parts

CNC machine tools are the types of machines that are most capable of producing the most complex parts with unmatched precision and efficiency. This is why such machines are the most suitable for machining geometries where efficiency and tight complex tolerance are essential. These machines use advanced technologies and features that can help them in machining tasks that other machines would probably be unable to execute. It is thus clear that most manufacturing industries will require the use of CNC machine tools to push the limits of what can be achieved in modern manufacturing. The outstanding capability of CNC machine tools to machine the most complicated part hinges on two technical capabilities as discussed below.

The capability of multi-axis machining precision

The first capability that enables CNC machine tools to be among the most suitable for producing the most complicated parts is their ability for “multi-axis machining operations. Whilst conventional machining methods rely on three axes of motion, the CNC machine tools are greater because they can operate on multiple axes at the same time. In this way, they can produce machined parts with higher precision and specifically designed geometries and complex surface contours. For instance, a 5-axis CNC machining center is able to maneuver cutting tools for 5 -axis of motion, each of which controls how the cutting tool moves in and out of the workpiece. With multi-axis precision machining capability, CNC machine tools can access hard-to-reach areas with ease, and with little or no set-up, they can produce highly valuable intricate parts. High-speed machining capability

Whereas multi-axis machining is one technical factor that makes CNC machine tools one of the most capable of producing the most complicated parts, another outstanding factor is high-speed machining capability. Like it is mentioned in the introduction, the CNC machine tools use advanced features and technologies to facilitate high-speed machining. These machines rotate the cutting tools in thousands of spins per minute, and in a minute, they can rotate once at a speed of up to 30,000 revolutions. It is also important to mention that while the cutting speed is of this high speed, the feed rate is at 100 inches per minute. These high cutting tools contact material at a speed very much higher than their conventional machine tool counterparts.

Advanced CAD/CAM integration

CNC machine tools are aided with advanced CAD/CAM software, where manufacturers can design the machining processes to produce the most complex parts. The software can be used to design the part geometry and find optimal toolpaths to achieve maximum machining efficiency and quality. Also, in the software, the operator can use simulation features to identify any collisions and control strategy optimization to maximize machining error-free ability. This includes all the tight clearance passages in parts.

Tight tolerance machining

CNC machine tools are great at achieving tight tolerances even with the most complicated parts. Specialized control systems and feedback devices help the machine “know” the positioning and repeatability of the position of the part or tool at and given time. For example, a CNC lathe could and can still would get.0001 of an inch, by taking a small cut and the same exact sized cutting pass, established tight clearances between two tight clearance passages. The clearance accomplished usually is able to machine even tight co-centric tolerances between a few holes or holes around a larger bore.

Flexibility

CNC machine tools can accommodate a wide range of applications and are the perfect machines for manufacturing complex parts with different sizes and tolerances. The machines can also be in industries dealing with a wide range of machine applications. Materials machine tools can process include all varieties of metals, plastics, wood, ceramics, composites and exotic materials. The tools can adapt to all of these materials, processing about any part or design

Supports multiple materials

CNC machine tools are versatile equipment able to machine a wide array of materials, which is essential for various industries where multiple materials are used for complex parts and components. They use advanced cutting technologies and tooling solutions to work with not only metals and alloys, such as aluminum, steel, stainless steel, titanium, and brass at maximum accuracy and quality but also with plastics, composites, and ceramics. The last includes alumina, zirconia, and silicon nitride, some of them used even in aerospace, the medical field, and semiconductor manufacturing materials. Each of them can be machined using CNC equipment to its maximum properties, etc., using diamond or carbide tooling solutions severed in various cutting strategies. For example, aerospace uses turbine blades and structural components, the medical field implants as well as semiconductor manufacturing substrates of ceramics.

Machining metals and alloys

One of the greatest advantages of CNC machine tools is the ability and capacity to coat metals and alloys, being able to achieve optimal results with cutting parameters. Maximum accuracy and surface finishing quality are ensured. For example, the only method to efficiently coat the material from the flat side is using a CNC mill equipped with carbide end mills able to remove metal material while keeping tightly set tolerances to reach the best surface finish quality.

Plastic and composite machining

Plastics, including ABS, PVC, acrylic, and nylon, composites, including carbon fiber and fiberglass, are machined to the utmost accuracy using various CNC machine tools and technologies. The latter include cutting tools and machining strategies to ensure high surface finishing quality and precision of dimensions. The market includes electronics, consumer goods, and aerospace industries where lightweight and durable materials are demanded for complex parts.

Ceramic materials

Similarly to plastic and composite materials, ceramics, such as alumina, zirconia, and silicon nitride, can also be used for multiple market purposes, including aerospace, medical implants, and semiconductor manufacturing. In all of them, the materials are used for their extreme hardiness, heat resistance, and corrosion resistance. Using CNC equipment and cutting solutions, ceramics are machined to their maximum precision, and the tolerance and reliability of cutting tools increase.

Low dependence on humans and less human error

CNC machine tools represent a technological type of equipment for various types of metal processing technologies that reduce the need to rely on operators’ skills. In this way, it can ensure a more productive, efficient, high-quality, and safer manufacturing process that lacks costly errors. Machines are characterized by an increased level of automation and use various control technologies making it possible to perform complex work programs without direct human involvement. The importance of the tool is in the ability to ensure production outcomes that are more uniform and reduce the risk of deviations from programmed parameters due to shifts or other factors. CNC machinery can provide motion control of the highest precision that will be suitable for the highest standards of precision production. Reduced setup time

The key benefit is the opportunity to minimize setup and changeover times between production runs because they can be programmed. Moreover, workpiece probing systems can further guide the setup process and ensure that their position is correct without the need for adjustments. It can ensure that positioning errors and induced uncertainties can be erased because machinery does not require manual setting. Minimized errors

These tools also are able to minimize the need for adjustments during working, including manual tool changes because of the options of automated tool changers that can be utilized. As a result, the time that is needed for adjustments between processes and the risk of subsequent mistakes is minimized. CNC machinery for metal processing can benefit organizations that want to ensure a higher level of precision and minimize the risk of deviances and errors.

Real-time monitoring and error detection

CNC machine tools are typically equipped with advanced monitoring and error detection systems that provide real-time performance monitoring and proactive error prevention for operators. These monitoring systems continuously monitor machine tool parameters, including cutting forces, spindle speeds, and tool wear rates. As a consequence, the machine tool promptly notifies the operator of any disturbances that may occur before they are transformed into a more severe error. For instance, by monitoring machine vibration, the CNC can instantly identify whether the tool is becoming worn or the machining conditions have been incorrect, providing a warning to the operator The CNC machine tool ensures that monitoring systems provide informational feedback and an error detection system, maintaining a substantially lower risk level of human error when manufacturing parts. Proactive error detection and real-time feedback suppress the possibility of parts being machined incorrectly and ensure consistent part quality.

Enhanced safety-related features

CNC machine tools feature advanced safety features and interlocks that protect the operator from all hazards related to machining. It is widely recognized that numerous interlocks, such as light curtains, safety curtains, and emergency stop buttons, must be implemented into standard CNC machines to provide operators with multilevel protection from any potential incident. Furthermore, CNCs themselves can be programmed to remain within the safe operating ranges of the machine tool and can restrict the operator from entering hazardous machine areas while the machine is in operation. The safety features significantly reduce the risk of human error in machining-related accidents and, as such, improve the overall safety of the machine tool at the workplace.

Improved reliability and uptime

One of the key advantages of CNC machine tools is their ability to improve overall reliability and uptime by reducing the dependence on human operators. Since these machines operate without the risk of human error, they may be used to continuously run manufacturing operations without the limits of operator fatigue. They feature diagnostic capabilities and additional predictive maintenance features that may be used to identify potential issues and notify operators well before they cause unplanned downtime. Thus, machine tool operators can continuously monitor their machines’ performance and conduct required repairs and maintenance in a planned manner that would not cause an interruption to production. As such, the use of CNC machine tools can provide a higher operational reliability and uptime, and ensure that manufacturers can produce products in the required amount to meet customer demand.