To find the ideal sheet metal fabricator, follow these steps: First, assess your project needs. Second, research potential companies. Third, evaluate their experience and expertise. Fourth, compare pricing and services. Finally, communicate effectively to finalize your decision.

Assess Your Project Requirements

Visiting every site and looking for the best one is an essential step to be taken with regard to sheet metal manufacturers. Nevertheless, it is necessary to assess the requirements and see if they meet the needs of the project. Sheet metal manufacturers can provide similar services and products, but without assessing customer requirements, it is impossible to understand if it is the right choice. To assess requirements as it was in the chosen case, the following steps need to be taken to evaluate:

-

Define the scope of the project. First of all, the type of components that need to be produced should be identified, with the following characteristics: size, complexity, quantity, material, and finish. For instance, if it is a question of an automotive application, it can be noted that tight tolerance and necessity to have a corrosion-resistant coating is required ;

-

Establish standards of quality. It should be decided on the quality of the work to be done and the characteristics of the finished product such as dimensions, surface finish, and compliance with any standards and requirements. It should be decided if any testing or controlling of the piece needs to be done;

-

Production volume. Since the amount of product that can be received at a ship metal manufacturer varies, it should be decided what the expected volume of products the given project is. As such, it is decision needs to be made which volume may be produced stunning from small prototypes of large-scale manufacturing;

-

Budget constraints. Decisions need to be taken regarding how much money it is possible to spend on the project, including the cost of materials, processing, labor, or any additional services or requirements that may be added to the product. It is better to get quotes from many manufacturers as it guarantees receiving the best price option;

-

Lead time requirements. It is necessary to decide when the manufactured pieces need to be shipped and delivered to the customer. Consequently, the company needs information about the lead time to understand whether the requirements of the customer can be fulfilled;

-

Specialized requirements. It is necessary to decide if there are any specialized requirements related to the company, meaning whether it has specific production processes, developed tooling, equipment, or experience in some material or application, which is needed to produce the given product;

-

Evaluate supplier capabilities. Research should be done regarding the company including its capacities, experiences, equipment, certificates, and reputation among other clients. A customer with a similar taste can provide additional information.

The criteria above can be used when evaluating the requirements of the customer decision to be made in terms of choice.

Research Potential Manufacturing Companies

If you are looking for the perfect sheet metal manufacturer, meticulous research on the candidate companies is a must. Here is how you can conduct a proper research and evaluation of manufacturing companies:

Use online resources

Use the power of the internet by searching through industry directories, search engines, and manufacturing association websites. Use proper keywords such as “sheet metal fabrication” or “precision metal manufacturing” to list the potential manufacturers that could be relevant to your project.

Check the company website

Visit the website of the candidate manufacturer to learn more about their capabilities, services, work space, equipment as well as past projects. Check if the company has a strong presence in your industry, or if you can find find similar types of projects for other companies. Also check if the company is certified, hold any awards or if favourite quality systems are used.

Read reviews and testimonials

Use the internet, as well as websites such as Yelp, Google Reviews or other manufacturing and engineering forums to read more about customer experience with the company. Tread reviews with caution as they might be biased, however you can learn a lot from other customers’ experiences.

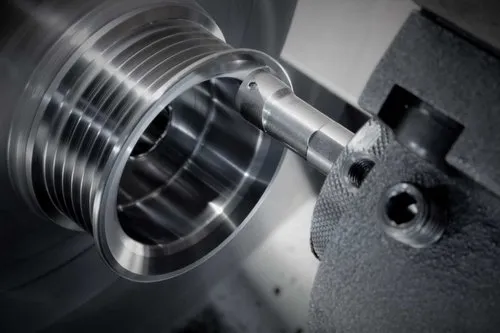

Check equipment and capabilities

Learn more about the equipment that would be used for your project and make sure that it could accommodate your needs: for example, a company should be equipped with high-pressure CNC laser cutting machines , CNC punching equipment, as well as automated machinery for robotic welding, edge deburring, and finishing . Equipment indicates the high quality and preciseness of parts produced.

Check location and logistics

Choose a manufacturer that is in close proximity to your company or the distribution centre in order to save on shipping costs and to ease on logistics and travel time between the two companies.

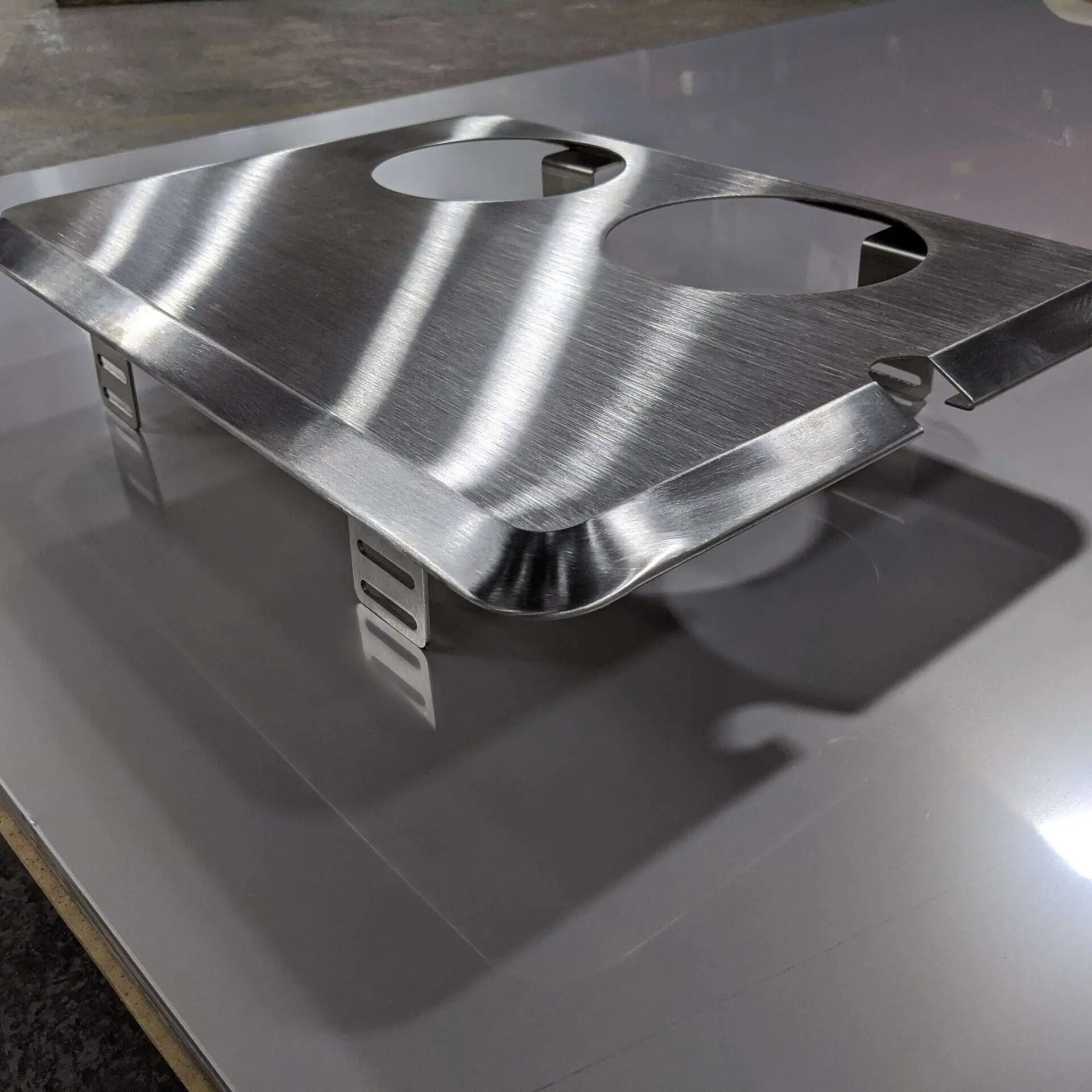

Request a prototype

Once you establish the list of viable companies, ask them to produce a sample or a prototype for you. Check for material consistency, surface finish quality, dimensional consistency as well as details in equipment.

Request quote

Call the companies or write an email with project specifications and request a quote. The quote should be detailed and should contain information about material costs, work hours as well as the cost of setting up the machines if it is applicable. Make sure to secure quotes from multiple companies to ensure competitive price and also consider the lead time for each manufacturer.

Communication

Finally, access the communication process and check the attitude of the company staff. Most companies are well-intentioned, however consider the responsiveness of the company staff, their efforts to understand your problem and answer your questions, as well as understanding and providing as many clarifications on the process.

Assess Experience and Expertise

It is crucial to evaluate the level of knowledge and experience of a sheet metal manufacturer to determine their ability to fulfill timely and precise orders for your project. The steps to evaluate a manufacturer’s experience and expertise are as follows:

Review industry expertise

First and foremost, the manufacturer you choose should be experienced in the industry of sheet metal manufacturing. Check their time of operation and evaluate the number of similar projects that they have completed in their tenure. In general, the longer the manufacturer is in businesses, the more they can hone their expertise and processes.

Look for specialized skills

Some projects may require unique and specialized skills, such as unusual processes or products. If your project requires a specific type of bending or forming, ask the manufacturer about their experience and knowledge of the process. Look for evidence of relevant training and certifications, as well as a portfolio of similar projects that the manufacturer has previously completed.

Examine past projects

A good manufacturer will not have any problems presenting their past projects. Check if the manufacturer has experience in similar sizes and scopes of projects, especially in your specific industry. Pay particular attention to the apparent work quality and the level of precision and attention to detail.

Ask about industry certifications

Ask the manufacturer directly about the quality standards and certifications that they have. Valuable certifications include ISO 9001 and AS9100, which can confirm the high quality and consistent delivery of the manufacturer. However, your organization’s specific requirements can also require additional certifications.

Evaluate technological dimension

Modern sheet metal manufacturers cannot compete without the use of advanced machinery and technological processes. Research which specific technologies they use and how their technological base can affect work quality. Consider using manufacturers that utilize CNC machining, laser cutting, and 3D modeling software for additional efficiency, precision, and attention to detail.

Compare Pricing and Services

In the process of search for the optimal sheet metal manufacturer, it is important to consider the opportunity to compare pricing and services for getting the best value for investment. The following suggestions aim at supporting this process.

Request for Detailed Quotes

The comparative pricing starts with the communication with each manufacturer to provide the comprehensive specifications of the project and receive the response. The details of the drawing, material requirement, dimensional tolerance, and explicit finishing requirements should be attached to the request for the quote . It is important to receive the itemized quote that describes the price of the material, labor, and setup alongside the additional pricings for separate services.

Analysis of the Cost Breakdowns

The pricing structures described in the two offers are reviewed to understand the specific details behind them, refer to them, and avoid hidden costs . Namely, reviewing the perceived pricing in terms of the material price, labor cost, overhead price, and taxes or tariffs will be useful. The goal is to find the transparency in the pricing of each manufacturer. Perceiving the additional costs for measurements such as quality, rate, and capacity of each manufacturer will be considered to make the final comparison.

Consideration of the Total Cost of Ownership

The comparison of the prices and service offerings should also include the total cost of ownership with the associated cost of shipping, customs taxes, lead times, and other risks or liabilities. The long-term costs associated with the sustainability of each manufacturer should also be mentioned in the comparison to receive the comparisons.

Assessment of Service Offerings

The evaluation and comparison of the range of services with the textual descriptions related to them are identified as another important step. The availability of additional services such as design assistance, prototyping, finishing, the assembly of parts, and inventory maintenance should be mentioned and compared. The exact details of each service should be compared for the possibility of providing the level of customization according to the requirements.

Communicate and Finalize Your Decision

After eliminating some of the options and choosing the manufacturer that can satisfy a certain number of conditions, it is important to communicate effectively and make a decision. The following is the description of the process that can help.

Schedule Meetings or Calls

It is suggested to plan minimal interactions with the selected sheet metal manufacturers that can help to answer several remaining questions. For example, it is advisable to schedule a meeting with a top manufacturer or call the two or three top available options regarding this list. During these discussions, it is possible to communicate more essential data regarding some aspects of the project to make sure that the performers will satisfy the owner’s needs.

Clarify Expectations

It is important to communicate the specifics of the project to the selected manufacturer properly and positively. It is suggested to use certain visual aids like CAD designs or other sketches that can adequately explain certain project requirements. Moreover, it is essential to provide certain examples and performances that can guarantee that the mission is understood properly. The other items that should be communicated to the manufacturer will include the desired time for delivery, quality management requirements, and the other options that should be discussed to reach an agreement.

Discuss Terms and Conditions

In addition, it should be noted that some of the issues that should be discussed with the manufacturers will be connected to terms and conditions of the contracts. For example, it is essential to consider the payment options, the period for delivery, and some other aspects of the work of the manufacturer. Finally, the owner must understand the quality of performance that is acceptable and agree on certain quality management solutions.

Request References

Moreover, the owner manager should also apply to the references of the selected manufacturers. In this way, it is highly recommended to require the list of the best references of the old clients of the manufacturer. In addition, it will be helpful to note the references of those clients who were involved in the performance of similar projects. In this case, it is essential to request the information from the two or three references of each manufacturer that was requested on the previous stages of the current research. The questions should be developed to prove the quality of the suppliers, quality of the performance, and some other aspects that can be completely evaluated with the help of references.