5 Proven Techniques to Enhance Sheet Metal Strength: Welding Ribs, Screw Attachment, Bend Tapers, Internal Reinforcement, Advanced Joining

Add Weld Ribs

Adding weld ribs is an effective way to improve the overall strength of metal sheeting. This technique allows for more even stress distribution across the material, which decreases the chances of failure under load. In performance, weld ribs will be added perpendicular to the primary stress direction. This way, the perpendicular weld ribs will be more likely to deflect stress evenly and not accumulate in one place, as, for example, parallel ribs would do.

The practice of adding weld ribs is relatively common, especially in the materials, where strength is desirable yet lack of weight is critical, for instance in the aerospace industry. Most of the material in an aircraft fuselage is composed of weld rib sheets along the fuselage, typically having weld ribs along the wing joints and pressure bearing sections . This allows for the structure to be extremely light and still solid; however, the addition of weld ribs must be planned carefully, so the added weight would not negate the benefits of uniformly distributed strength. In the case of weld ribs, the technique would be as follows:

-

Analysis of Stress Points via Finite Element Analysis or another stress simulation. Find out where the metal sheet will accumulate primary stress under loads.

-

Design of Rib Geometry. Calculate the size, placement, and shape of rib welds overall and in specific areas. This usually can be done as to fit even weld ribs into evenly distributed stress points.

-

Material Selection. Choose a welding material along with a suitable BHM-3 basal surface that could be welded to the sheet metal and also be applied with limited frequency. It also must demonstrate fatigue resistance, as stressed parts may be subjected to repeated cycles of pressure.

-

Welding Process using TIG or TIG welding. Make sure all welding occurs on a minimal basis to make sure the results are secure and initiated at all pointy edges or base of weld ribs. Use rigorous quality control post-fix or even non-destructive testing to assess weld strength via ultrasound testing extensively or X-ray to detect faults in the weld.

Fix Ribs with Screws

A practical method of reinforcing the strength of metal sheeting is fixing ribs with screws. The process refers to attaching ribs to the metal sheet using the crew, which helps to support it and maintain stability. It is often used in conjunction with the construction of industrial equipment cabinets. When constructing the metal panel, experts place ribs and fix them with screws onto the panels. This added external support to the sheet enhances the overall strength of the cabinet, which allows it to endure the heavy loads and rough use that are characteristic of industrial use. Below is the step-by-step recommendation on fixing ribs with screws.

-

With the help of a stress analysis and your design requirements, make the decision about where to place the ribs within the metal sheet. Make sure that the ribs are located evenly to divide the stress.

-

Choose the appropriate screws. To fix your ribs on the right you will need to choose a screw with the right size, material, and right pitch thread. Main criteria for selection include corrosion proof and load capacity of the screw.

-

Find the right configuration of a screwdriver and drill the screw holes into the metal surface. Make sure to drill them precisely with clever equipment to avoid any complications while fixing the screws during the final step.

-

Align the ribs with the holes on the metal panel and fix them in the appropriate place with the help of a screwdriver. Make sure that at the end of the procedure they were tightened to the required torque without marking the metal panel during the fitting.

-

During the final examination make the sure to check that no missed ribs and misaligned holes, as well as all the screws. If the operation was performed successfully, the resulting assembly will exhibit the quality of the reinforcement rack.

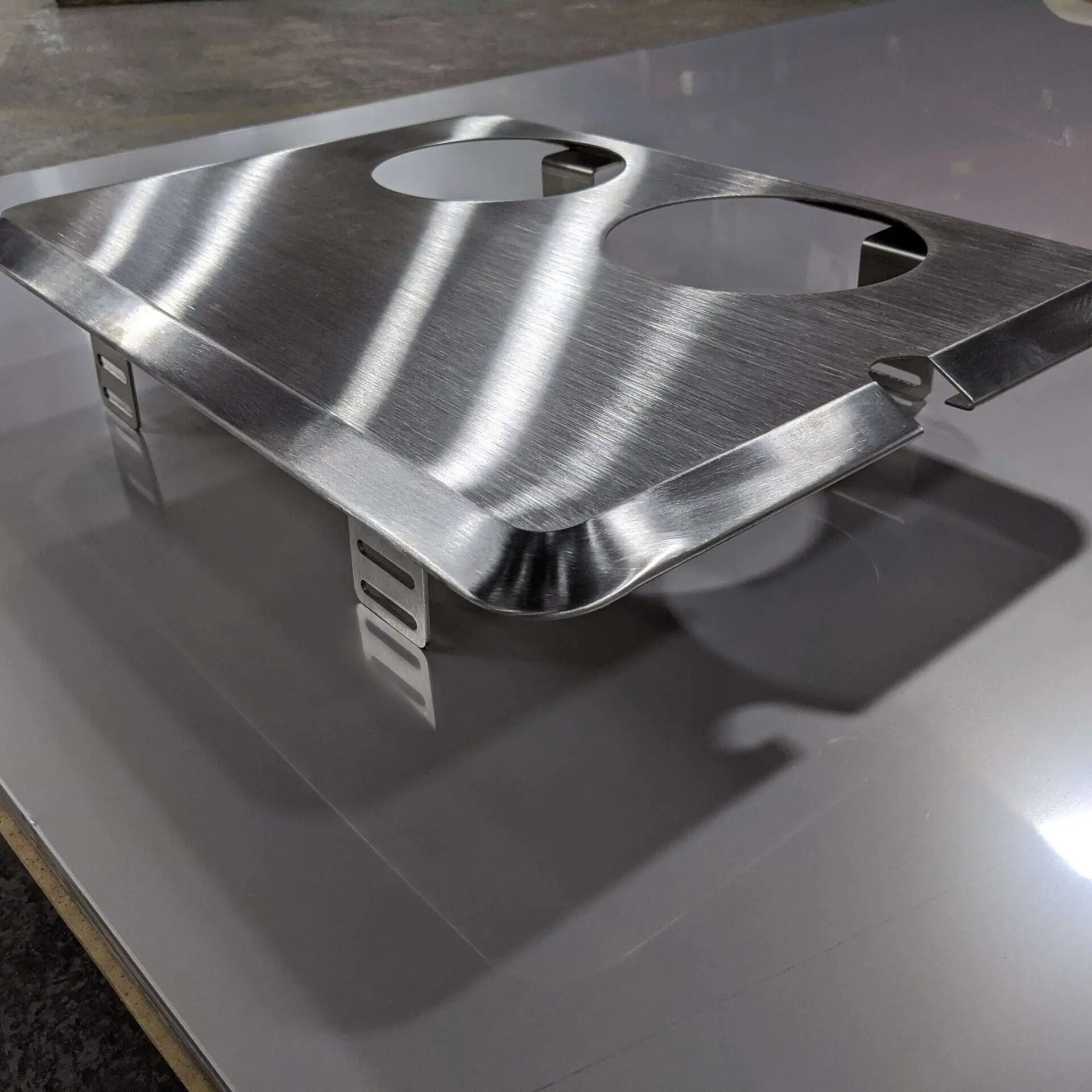

Add Taper to Bend

Adding a taper to bends is a useful method of metal sheeting reinforcement. The idea is simple – by gradually tapering the thickness of the material at the bend point, one can prevent stress concentration and create a stronger and more durable structure. The best example of this technique’s application is in the automotive industry. Here, manufacturers create lightweight but extremely durable bodies and chasses for vehicles. Most sheet bends in these products are tapered. This feature allows manufacturers to provide their products with better strength, stiffness, and reduced material usage.

The process of adding a taper to bends requires extreme precision and attention to detail. Here is a stepwise guide on how Tata Motors, for example, adds taper to its sheet products:

-

Calculating the bend radius. The optimal bend radius should be calculated based on the properties of the material and the desired taper angle. The goal is to create a smooth transition without concentrating stresses on the material, which can be challenging. Thus, the calculations should be as meticulous as possible.

-

Designing the taper. The product’s taper can be more of an art than a science, but the developer should still calculate the optimal taper angle and length. The goal is to ensure that the stresses will be evenly distributed along the bend line. The taper should gradually decrease its thickness from the bend point to the outside edge of the product.

-

Selecting the tools . It is vital to choose the optimal bending tools – usually, press brakes or rollers. They should be precise and strong not to deform the material or to create other imperfections on the sheet.

-

Bending. The bending process should be carried out with meticulous attention to detail. Control the material to prevent accidental distortions and verify the taper shape against the developed design.

-

Quality control. After tapering the metal bend, one needs to carefully measure its angle and other characteristics, using calipers, laser beam measuring tools, and other measurement instruments.

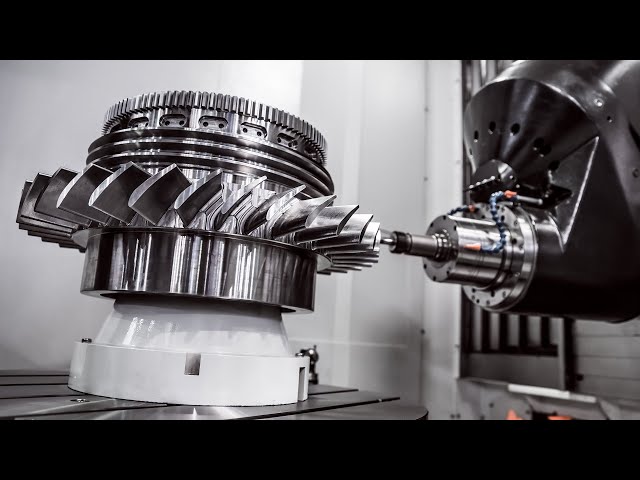

Insert Reinforcement Material into the Bracket

Inserting reinforcement material into the bracket is a robust and effective method of increasing the strength of metal sheeting. By adding alternative material to the composition of the bracket, its load-bearing capacity and deformation resistance can be substantially increased. Such a method can be utilized, for example, to build heavy-duty shelving units capable of storing enormous loads of goods in warehouses. In this case, insert reinforcement material would be used for the bracket to increase the modifications and improve stability. Adding steel inserts or using composite reinforcement material, such as fiberglass, would allow manufacturers to ensure the top performance of their shelving units under maximum loads.

The process of inserting reinforcement material into the bracket includes several specific steps:

-

Analysis of the bracket

-

Material selection

-

Modification of the bracket

-

Insertion process

-

Integration with the assembly.

The analysis of the bracket should be done specifically for building the bracket with insert reinforcement. It should include a detailed inspection and comparison of the options and take into consideration both deformation and load-bearing properties of the bracket. As insert reinforcement can improve both kinds of performance, the specific needs should be identified first. The next step is selecting appropriate insert material that should be strong, solid, and compatible with the base metal used for the bracket . The main insert materials include steel, composite fiberglass, and carbon filters. As for the last step, it can include machining and welding technologies to develop the final form of the bracket, as well as insertion of the reinforcement material with similar methods.

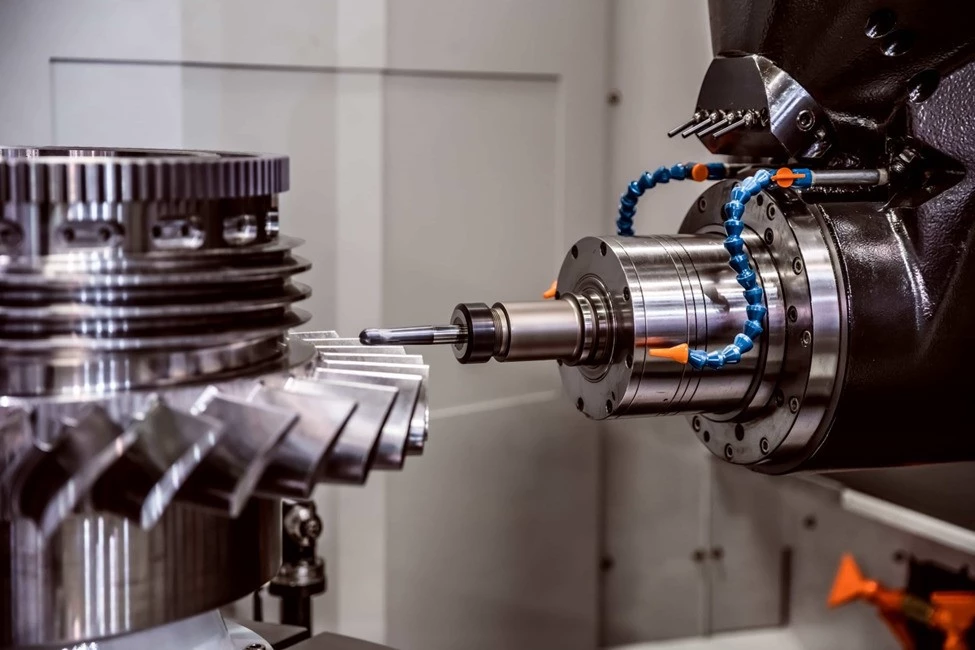

Leverage Advanced Connectivity Technologies

The cutting-edge approach to enhancing the strength of metal sheeting is the application of advanced connectivity technologies. For instance, in offshore oil rig construction, the use of IoT sensors and communication systems help ensure that offshore platforms are safe and that the metal sheeting will not fail. Engineers utilize the mentioned advanced connectivity technologies to monitor temperature, pressure and vibration in real time and successfully track the integrity of the metal sheeting. Also, in order to predict issues, they adjust to such changes and failures in advance and identifying and applying corrective measures before the catastrophe happens.

The process of leveraging the connectivity technologies to improve the strength of metal sheeting is detail-intensive, and it involves the following steps:

Sensors selection and Integration

Identification of the factors that have the most potent effect on the strength and residual performance of the metal sheeting. For instance, the use of different scenarios of stress, strain, and corrosion helps identify the key factors and allocate where sensors should be placed .

The correct selection of the sensors based on the identified factors and utilization of the sensors to track the changes such as the change of stress, strain and corrosion allows continuous identification of the factors leading to potential failures . Installation of the selected sensors on the vulnerable parts of the offshore oil rig helps achieve the measurement of the key factors and predict the form of changes and failures and make corrective measures to prevent potential critical failure.

Data Acquisition

Initiation of a data acquisition system. The sensors should be connected to the main hub, which may be placed either on the oil rig or in a separate location. It is possible to treat data acquisition as the arrangement of wired or wireless network of nodes, sensors and communication devices with sensors transmitting the data wirelessly data through nodes to the hub for wired communication. The setup helps ensure the collection of real-time data that is continuously transmitted to the main hub.

Utilization of USB or COM serial protocols like MODBUS to transmit the data to the servers situated near the oil rig or directly into the cloud helps achieve the data acquisition and analysis. Transmission of the data directly to the servers is easily done by the application of SIM card-modem connected to the GPRS circuitry.

Data Analysis

Implementation of advanced algorithms and analytics helps track the patterns and get the most of the data and utilize the sensors for the benefits of an enterprise. For instance, the application of regression analysis and machine learning helps predict the residual performance and effectiveness of the equipment.

Utilization of the data enables highly efficient estimates regarding the moments when such preventive measures as welding of reinforced patch steel or tubes should be implemented to prevent corrosion and make the equipment serve for long. The data analysis helps engineers receive precise estimations about the strength and issues of the metal sheeting and it helps develop measures to prevent cracks and ruptures.

Proactive Maintenance

Early identification of the potential of early failures through sensors and the data analysis allows the successful initiation of proactive maintenance strategies. The considered strategies involve the identification of the longevity and time of operation of sensors before transmission or their resetting .

Replacement with new sensors is inevitable, and engineers should identify when it is time for such replacement. Since the application of sensors to predict corrosion and wearing is critical for the calculation of the time when such preventive measures as the application of ropes, rods, and tubes of high quality should be applied for the reinforcement of oil rig parts.