5-axis machining offers enhanced precision, complex geometry production, reduced setup times, improved surface finishes, and extended tool life over traditional methods.

Main Advantages of 5-Axis Machining

Increased Precision and Accuracy

5-axis machining technology is ideally placed to deliver unmatched precision and accuracy in part manufacturing. This is because the tool can cover five distinct axes in a single pass, leaving both the workpiece and the tool in optimal conditions across a variety of geometric shapes. Oftentimes, such precision can be as much as within microns, a requirement in the aerospace industry for airfoils and engine mounting that cannot be within 0.0001 inches. As a result, parts fit seamlessly and without any post-processing that is particularly vital in high-production and cost-sensitive environments.

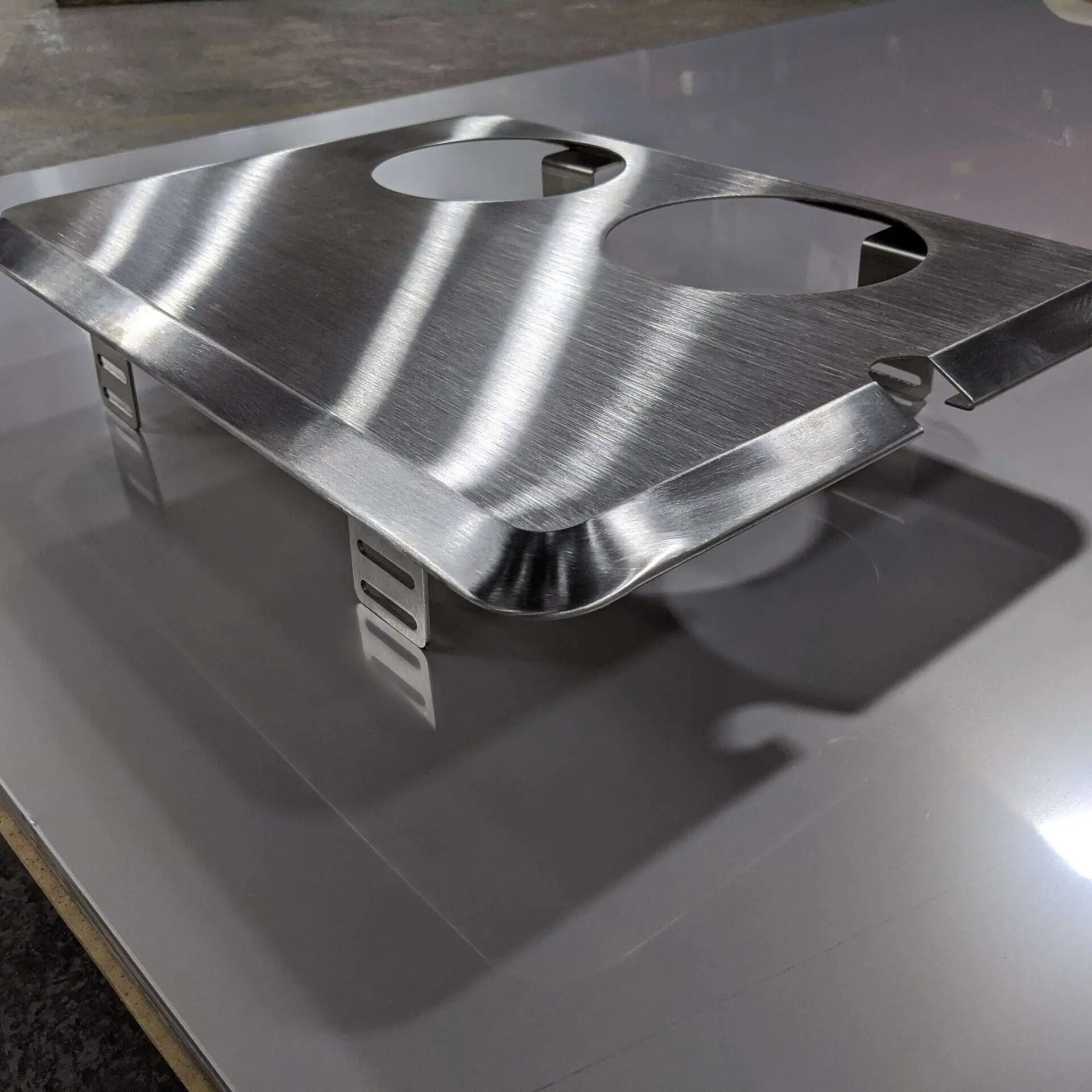

Complex Part Geometry

A significant advantage of 5-axis machining technology is its capability of handling complex geometry in a single setup. The technology is known for its ability to develop geometric features of parts that could not be achieved in 3-axis systems with simultaneous embrace. This advantage is essential as it eliminates the need for multiple setups which takes longer as well and heightens the chance of error between outputs during setup changes. A good example illustrating this point is the traditional approach to producing a five-sided cube, which involves five different setups. At the same time, the 5-axis strategy will feature a single setup only. This ability is vital in the automotive industry where both unique shapes and deeper contours feature on the dashboard panel, headlights, and other parts.

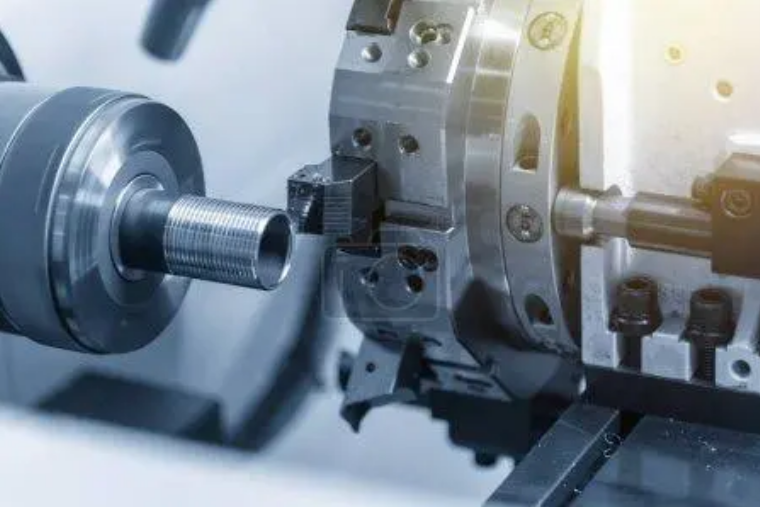

Reduced Setup Time

Another significant reason to embrace 5-axis machining technology is that it significantly reduces setup time. The ability to machine all sides of parts saves time across the entire production cycle as all the areas will be machined there and then. For instance, this could save time and shorten cycle times, which is particularly valuable where product development needs to be timely as in the case of the production of medical devices. For example, the setup time of orthopedic implant machining is reported to have been reduced by up to 70% and established in manufacture.

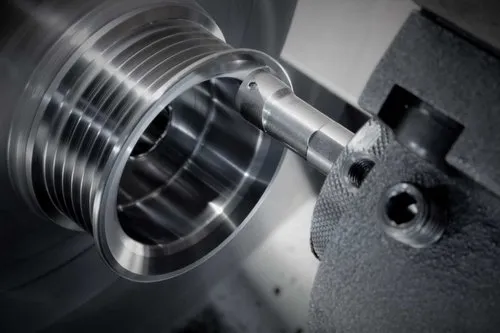

Superior Surface Finish

Another noteworthy advantage of 5-axis machining technology that is particularly relevant to the automotive industry is that it provides unparalleled surface finish to the produced parts. This is so because the machining requires the tool to always remain in an optimal position in relation to the surface of the workpiece during the entire cycle. As a result, the tool will not require hand polishing or manual finishing. This process is typical for the automotive industry for the production of mirror housings and custom rims, with the produced parts running far smoother and aesthetic than customer expectations.

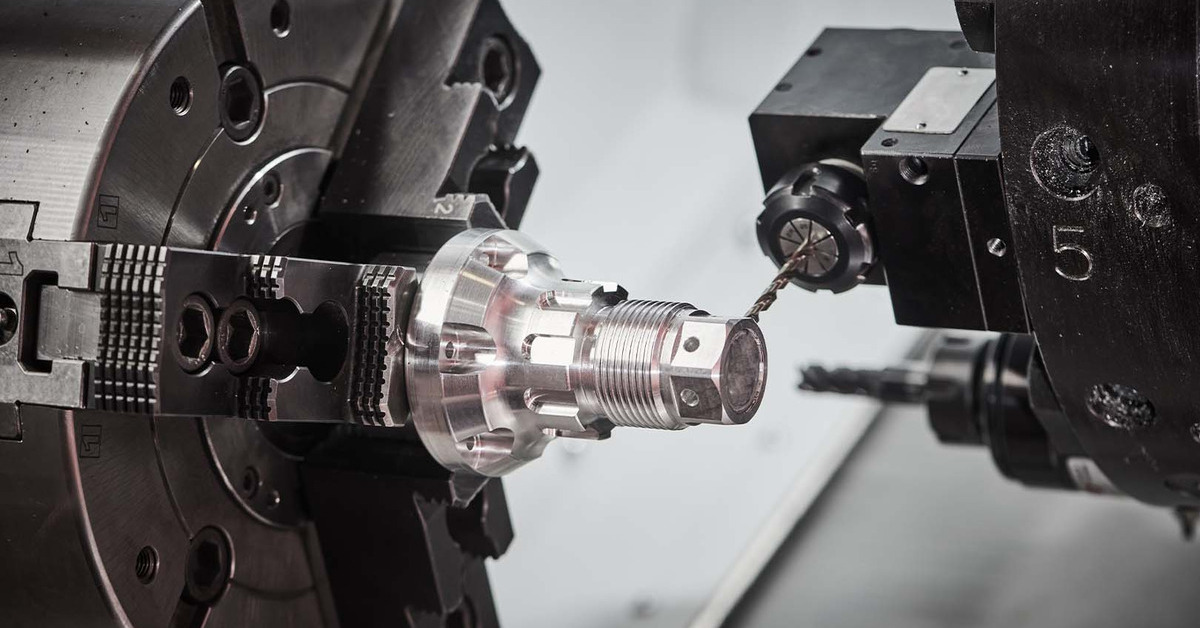

Tool Life Improvements

Another significant and practically valuable advantage of 5-axis machining technology is that the tool path is produced with utmost precision, ensuring the durability of cutting tools. In other words, the cutting tool never leaves the workpiece during the machining process, ensuring that materials are not wasted and the tool does not experience undue wear. This improved tool life is particularly important for industries producing energy-related parts as tools wear incredibly quickly when cutting exotic and harder metals. For example, components made of these materials used to have their throat cut every 1000 parts. At the same time, on a single 5-axis machine, the tool is considered brand new after 3000 parts, improving part life and reducing costs.Complex Part Geometry

A distinctive and striking feature of 5-axis machining is the ability to handle details with intricate and detailed geometries, which traditional methods cannot. Using this technology, a machine interacts with the detail from five different axes at the same time, which makes the production of geometrically complex components an order of magnitude easier.

To prove this advantage by a practical example, consider manufacturing automotive turbocharger impellers. These parts have minimal destructive and curved features, just like the profile of wings and blades. With this feature, it would be difficult to produce them using a 3-axis method. However, 5-axis machining allows manufacturers to complete these parts in one setup, eliminating the alignment issues that could be caused by multiple setups in traditional methods.

The main steps in machining such a part, as well as general operations retaining to the usage of complex geometry, are:

-

Programming the machined paths. To generate them, engineers use advanced solutions, such as CAD/CAM software, which provide detailed instructions. They allow the machine to travel along the best paths and adapt to factors such as rotation, tilt, gouge or collision avoidance.

-

Machine setup. It is placed so that the part does not have to be shifted or repositioned for its spindle reach to every face. The part is then attached to a fixture like a vice or a set of clamps ensuring it remains stationary.

-

Machining. The machine removes material by executing the paths programmed in its computer. It also dynamically adjusts the angle and the depth to reach and cut the spots of the desired geometry.

-

Quality check. After the operation, the part is carefully measured using precision tools to ensure that all specifications are met and tightened.

Industries that require the manufacturing of deep pockets, sharp angles, or other complex features into their parts, would benefit from this operation. For example, aerospace always uses 5-axis machines to create airfoil geometries. These precise parts must be this detailed and accurate to match the extreme conditions of the flight. As a result, not only does 5-axis machining save time, but it maintains the high quality of modern industries as well. This approach eliminates waste and increases efficiency, which is why high-tech sectors prefer to use it.

Reduced Setup Time

One of the key advantages of 5-axis machining is its ability to significantly reduce setup time, which greatly improves production efficiency in various industries. This is due to the possibility of simultaneously moving along five different axes, allowing manufacturers to produce complex parts without having to move them to another setup. The process not only speeds up production cycles but also reduces labor costs and minimizes the risk of human error. The experience of 5-axis machining shows that for the production of an orthopedic hip implant, a part with a complex curvature requiring very high precision work, the following processes cut setup time dramatically.

Single Setup Processing: the manufacture of the implant is carried out “in one go”, with the machine able to perform almost all setups and angles for the part without the need for human interference.

Automated Tool Changes: the machine switches tools independently for machining work on different features of the implant, eliminating the need to manually change setups.

Continuous Operation: the machine works continuously without the need to stop for re-setup, which also ensures a high degree of production.

As a result, manufacturers were able to cut their setup time by 50% to 70% compared to their previous process using 3-axis machines. The higher the complexity of the parts and the more setups that had to be used for part production, the shorter the time saved. The time savings achieved are particularly important in the automotive and aerospace industries, where reducing time-to-market is essential. In the aerospace sector, exposure time was reduced from several hours to several minutes, which is critical to staying competitive in markets where both quality and time are customer success factors. This new process helps companies reduce production time but also radically improve business efficiency by managing their resources and ultimately cutting costs.

Improved Surface Finish

One of the essential advantages of 5-axis machining is a significant improvement in the quality of surface finish on machined parts. For industries where the surface is required to be not only decently finished but refined on its aesthetic and functional qualities, this technology works by optimizing the angle of approach of the cutting tool. The impact of the tool on the surface is minimized, reducing the marks, scratches, and blemishes that appear as a result and producing a superior surface.

Consider the cutting of a custom part for an automobile, such as the dashboard panel or the exterior trim:

Tool Orientation: The 5-axis machine adjusts the orientation of the tool constantly, ensuring that it is at the best angle for every curve and contour of every surface, cutting and erosion only where desired and leaving the surface without the need for secondary finishing.

The tool should maintain a constant point of contact with the material, ensuring an optimal, uniform surface texture and quality.

The frequently used advanced high-speed cutting techniques allow for increased speed of cutting with minimal thermal impact, which provides an additional level of surface finish as less surface roughness is observed.

Moreover, it is reported by manufacturers that the surface roughness of the machined parts produced by the 5-axis is typically 80% less rough than those cut by the 3-axis machining equipment . These results have not only provided for better visual characteristics of finished pieces but for their increased resistance to fatigue and corrosion.

Lastly, the 5-axis machining technology is most applicable in the aerospace or medical industries where the surface of the parts directly or indirectly impacts the performance and longevity of the parts. For instance, in the former, smoother parts produce less air resistance for the airframe parts of aircraft. This, in turn, implies that interested companies can cut parts with a high-quality finish directly. This allows them to deliver a high-quality product and eliminates the need for extra finishing costs to get the product to a saleable level.