To choose the right CNC screw machining service, assess their expertise, technology, quality control, flexibility, customer service, and cost effectiveness.

Assess Experience and Expertise

When you need to guarantee that all of your manufacturing demands are met with precision, utilizing the services of a CNC screw machining service with broad experience and expertise in the area is essential. The first step toward that goal is examining the number of years of the company’s tenure. In general, a company that has been working for over 10 years is likely to be one most stable and reliable one. Next, evaluate the company’s portfolio and consider which of the projects in the collection are similar in complexity and in scope to yours. For example, if you must create parts for the medical sector, note that a provider that successfully completed similar projects in the past is likely to be more reliable.

Evaluate Machinery and Technology Used

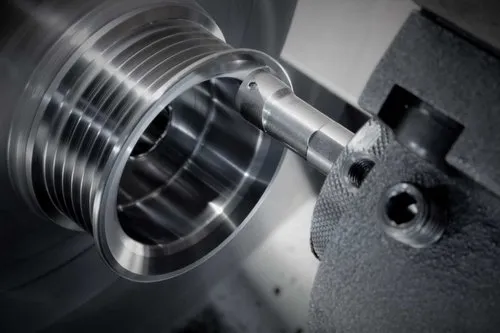

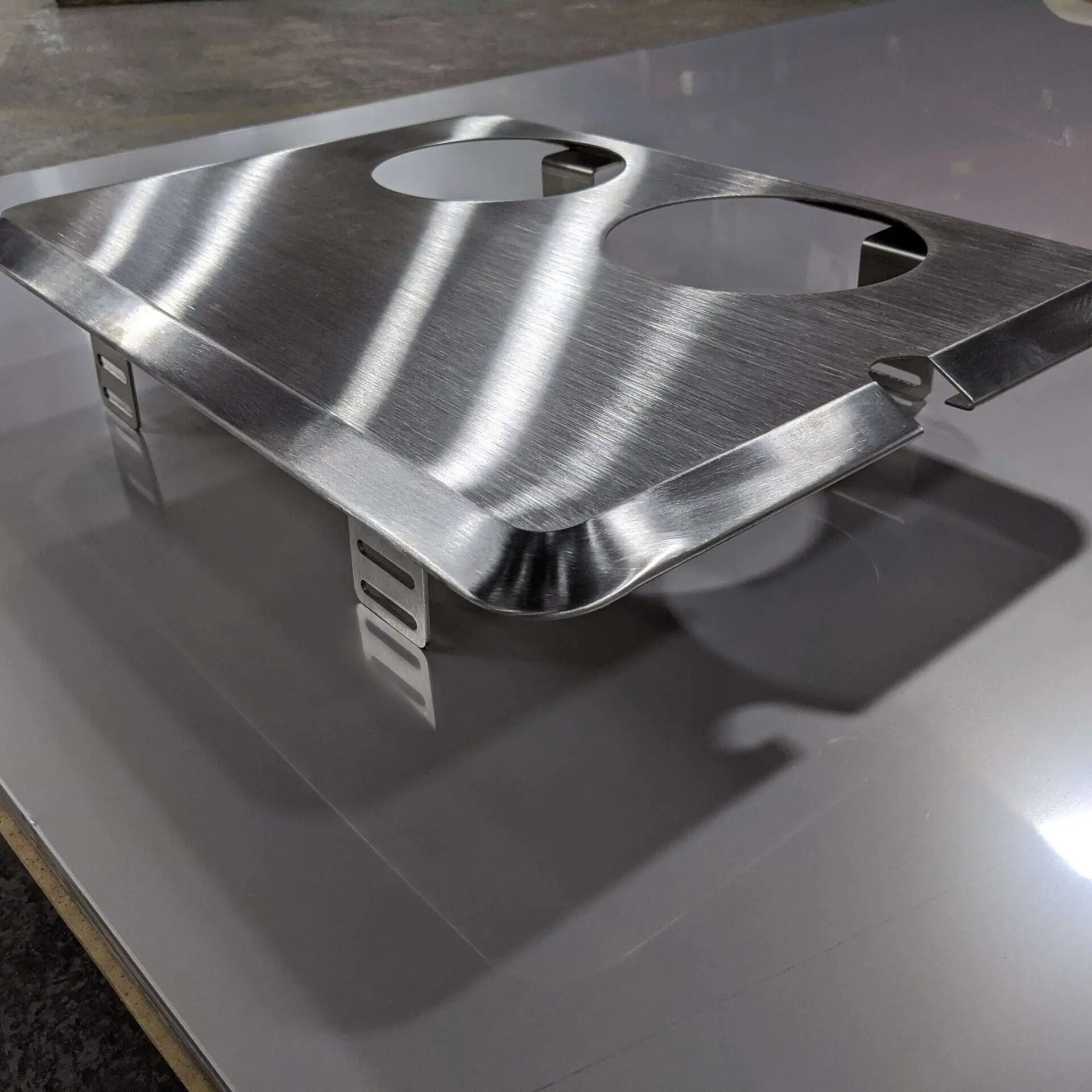

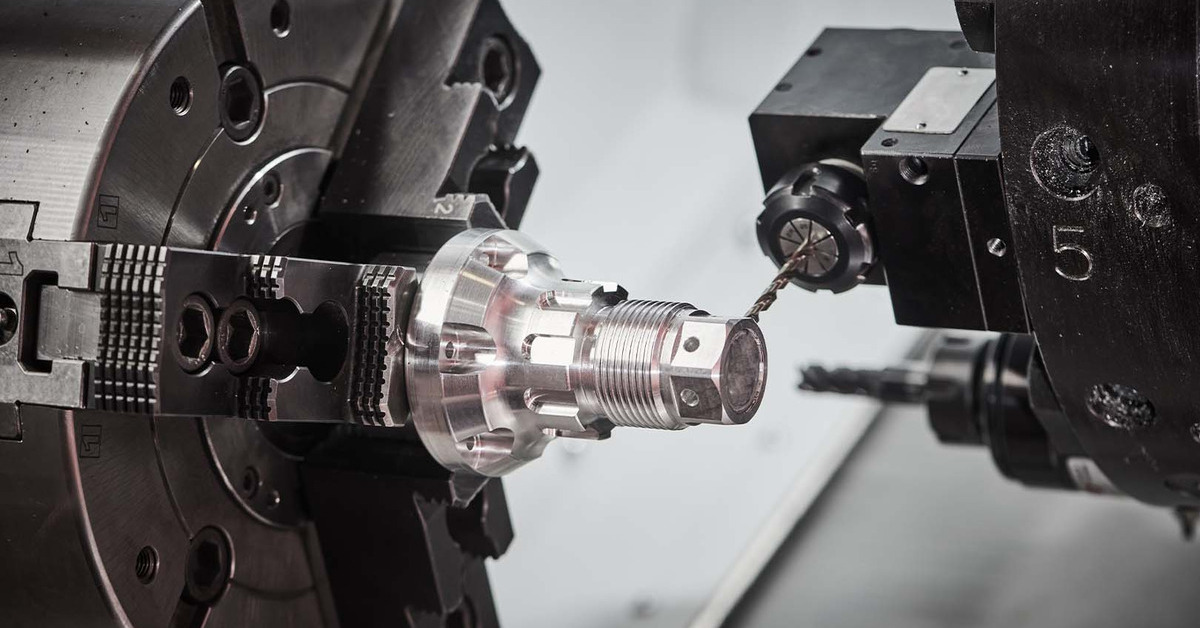

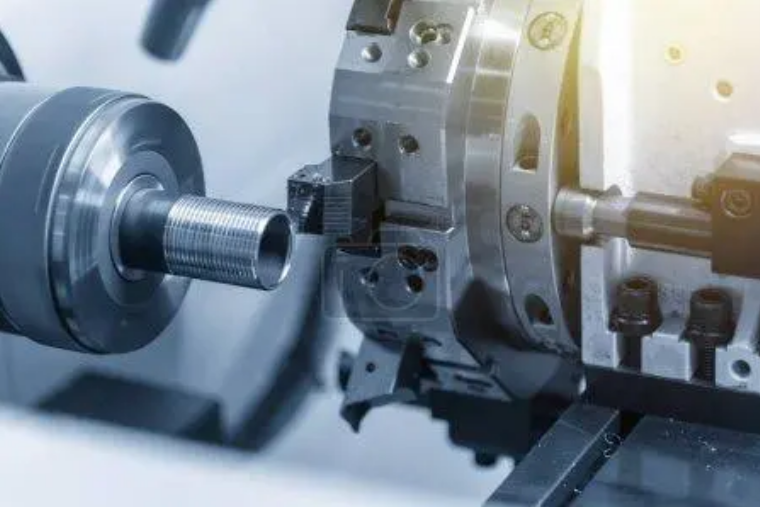

In addition to the experience and the competence of its workers, the technology that a CNC screw machining service utilizes is also of the utmost relevance. To guarantee that the provider uses the most suitable machinery and technology, ensure that each machining system is of the latest generation and less than five years old. You might also be able to assess the equipment in person during a visit to the company:

-

Check if the machinery can handle the complexity and size of your project.

-

Inquire into both the maintenance of the systems during operation and into when the last upgrade was.

-

The best question to ask is whether they use the latest generation of CNC systems.

Check Quality Control

Another primary concern here is how thoroughly the CNC screw machining service checks the quality of the products. The ideal situation is for the company to have a robust quality control system based on universally recognized standards, such as ISO 9001. In that case, you are likely to be able to request the latest audit reports and the relevant certificates. Ask the company how many defects they had in the past year and how it is that they minimize errors. For example, the optimal answer to that question is a step-by-step process with automated scanning and experienced technicians making periodic manual checks of the materials and the ready products.

Among the most important factors to consider are their ability to meet your deadlines and their flexibility. Not all businesses operate the same way, and your CNC service should be able to adjust to your business’s needs. Ask them about their average lead times for projects similar to yours and whether they have a contingency plan in case of unexpected delays. Additionally, make sure that they have the capacity to increase or reduce the scale of your production as needed and that they can easily accommodate last-minute changes in your designs and plans.

A good CNC machining service should also have excellent customer service and be easy to communicate with. Indeed, simply reaching them and getting a clear answer to your question via phone or email can tell you a lot about the reliability of the company. Ideally, they should also have one point of contact assigned to your account and be fluent in all the intricacies of your particular needs. This will allow you to get prompt and accurate updates on the progress of your orders and quickly solve any issues that might arise.

You should have a detailed understanding of the cost and supply the CNC service provides and how it measures against other potential providers. Discuss the details with them and request itemized quotes that clearly spell out the cost of materials and machine time, as well as any secondary services such as assembly or finishing . Compare these quotes to the industry averages and ensure that there are no hidden costs that could put a strain on your budget at a later date. You should also remember that the cheapest option is not always the best one, especially if it is unable to provide the quality or reliability your project requires.

Evaluate Machinery and Technology

It is vital for any company that needs to manufacture parts with CNC screw machining technologies to select the service that uses the latest and most appropriate technology. You can do it by looking for a group that buys new CNC machinery on a regular basis. Therefore, it is appropriate to ensure that the machinery that will be used on your particular part is no more than five years old. It is also possible to ask what type of machinery the manufacturer will use . It can also be useful to ask to tour the manufacturing facility to get a sense of how the machinery operates.

Another important issue concerns how often the CNC screw machining service updates the machinery. The service you buy has to be fast at updating the machinery, as the development of these technologies is currently quick. It is appropriate to check if the machinery of the service that you are planning to buy has all or some of the automated and precision capabilities required . Frequently, companies using CNC screw machining technologies for parts production rely on a software for programming and simulations that can also provide maximum accuracy machining ability.

Understanding if the service you plan to buy from uses cutting-edge CNC screw machining machinery is very important when you need precision parts. To conclude, selecting a CNC screw machining service that uses the latest and the best technology is possible if you take a tour of the manufacturing facility and learn more about the machinery that the service has. Moreover, it is appropriate to ask how often a certain company is changing the machinery. It is a great way to ensure a reliable and effective partner, which is vital for any business.

Check Quality Control Processes

While evaluating the quality control of any CNC screw machining service, it is critical to look into their processes in detail. Strong quality control ensures that the parts produced are uniform, reliable, and without defects. Here are a few things to ask the service about to see if their quality control is top-notch:

-

Conformation of Certificate: As most machining services should have one, ask for their current certification. Such certifications may include ISO 9001 or AS-9100, indicating the CNC service is up to international quality standards. Ensure it was awarded by a proper and authorized accrediting body.

-

Attention to Incoming Materials: Many poor-quality parts are a result of defective materials, so ask about their processes of inspecting incoming materials before they start production . The service should test materials extensively, including dimensional inspection and material composition analysis. Allowable differences should not exceed certain standards, and all raw materials must meet that requirement.

-

In-process Inspection: Besides, one inspection during the manufacturing is not enough. On what basis are the parts inspected and monitored during the multiple steps of the manufacturing process, how often are these steps, and what specifically is measured? The use or absence of Statistical Process Control can be a good indicator of advanced quality assurance.

-

Testing of Final Product: Before shipment, all parts should go through a comprehensive inspection. Are they using sophisticated measuring devices like CMM or laser scanners to ensure each dimension and tolerance is as they are supposed to be?

-

Treatment of non-conforming parts: Lastly, the service should have a plan to isolate and identify non-conformances. Do they have methods of tracking the defects and subsequent corrective actions to prevent the same defect from happening again?

Reputable CNC screw machining services should have strong and robust quality control processes. After examining these five aspects, one can be more confident in the quality of the partnership with the chosen machining service.

Consider Turnaround Times and Flexibility

In the manufacturing world, turnaround time and flexibility are as important as the quality of the products. When selecting a CNC screw machining service, you must evaluate their ability to maintain adequate production time and adjust to changing demands. Hence, lead times, response to rush orders, ability to adapt production according to project or order volume increase, and communication during the change are the four essential indicators of a company’s production capacity.

Start with asking about the average or estimated lead time for projects similar to yours. It is better to start by asking for specified examples of past projects similar in size and scope to those you are planning to complete. Second, ask if they offer any expedited services and the lead time they offer for rush orders. Additionally, inquire whether there will be any fee charged for the service. Lastly, assess the way they can handle changes in your project. Increase in order volume or a late design change exemplify some potential changes. You must ask how they respond to each case. The service must be able to exhibit its capability to manage these changes.

One more essential factor is the communication strategy for production adjustments. A good provider calls its clients in advance to let them know about changes in schedule. Hence, it will try to maintain production changes within them. If there is a change, a competent manufacturer will try to make it as invisible as possible. Therefore, apply this strategic approach and evaluate whether companies up to these standards. These indicators will help you avoid time problems during the project and will assure you that your business partner can adjust production to your changing needs.